About Suspensions

The Role of the Suspension

A suspension has three basic functions.

1

Supporting the vehicle’s weight

Springs

The vehicle’s weight is supported by means of springs. The spring constant determines the vehicle’s posture (vertical position and height from ground) and how much the tires travel (stroke).

Arms/Suspension Member

Links or suspension arms determine the motion of the tires. Link movement—in other words, the direction and position of the tires—changes the alignment (toe and camber angle). Changes in the alignment in turn change the handling stability. Suspension members or a subframe are used to attach links in order to improve the accuracy of their movements. With the engine and steering gear box attached to the front suspension and the differential attached to the rear suspension, a variety of forces are applied to the Suspension members. A stabilizer bar is also attached to assist the springs.

3

Absorbing forces from the road to protect the vehicle body and passengers

Shock absorbers

The springs absorb forces from the road. Shock absorbers or dampers absorb the vibration of the springs and determine the speed at which the springs move.

Rubber bushings between the links and Suspension members as well as rubber insulators at the point of contact between the Suspension members and the body also have a force absorption effect.

Basic Suspension Types

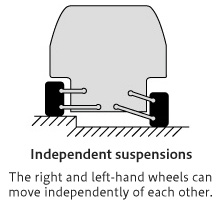

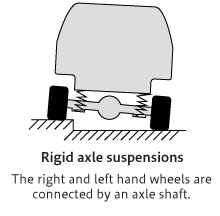

Basic suspension types can be broadly divided into two.

Independent suspensions

|

【Advantages】

|

【Disadvantages】

|

Standard types

- MacPherson strut

- Double wishbone

- Multi-link

- Torsion beam

MacPherson strut

- ① Shock absorber and spring

- ② Knuckle

- ③ Lower arm

- ④ Steering gear box

- ⑤ Stabilizer bar

- ⑥ Stabilizer connecting rod

This suspension is named for the engineer who developed it, Earl S. MacPherson. In this suspension, the top of a strut with a spring mounted around the shock absorber is attached to the body. The bottom of the strut is attached to the knuckle, and a lower arm is attached between the knuckle and body.

There are different varieties of lower arm depending on its shape, such as I-type and A-type. The lower arm is also known as a transverse link.

【Advantages】There is little error in wheel alignment because of the high attachment point of the shock absorber to the body. It also provides superior strength. It is inexpensive, as there are few components, which also creates more space for the engine. |

【Disadvantages】Bending stress is applied to the strut because of the deviation between the strut axis and input axis from the tire, so smooth movement is difficult to achieve, resulting in reduced ride comfort. |

Double wishbone

- ① Shock absorber and spring

- ② Knuckle

- ③ Upper arm

- ④ Lower arm

- ⑤ Steering gear box

- ⑥ Stabilizer bar

- ⑦ Stabilizer connecting rod

This suspension has a pair of upper and lower arms, each attached to the body and the knuckle. It is called a wishbone suspension because the arms originally resembled the V-shaped breastbone of a bird (a wishbone).

【Advantages】There is a lot of freedom to change wheel alignment and control vehicle posture. Handling stability can be increased due to high suspension stiffness. By attaching the arms to suspension members, vibration can be isolated without sacrificing suspension stiffness. |

【Disadvantages】The structure is complicated and there are many parts, increasing cost and weight. There is less engine room, as a lot of space is needed for the suspension. |

Multi-link

- ① Shock absorber and spring

- ② Knuckle

- ③ Upper arm

- ④ Lower arm

- ⑤ Steering gear box

- ⑥ Stabilizer bar

- ⑦ Stabilizer connecting rod

This suspension has four or five links per wheel, with each link connected to the body and knuckle. After the suspension on the Mercedes-Benz 190 was named “multi-link” in the 1980s, cars with suspensions referred to as multi-link started to be installed in Japan as well.

【Advantages】Handling stability and ride comfort can be achieved at a higher level than with the double wishbone through the effective positioning of the multiple links. |

【Disadvantages】The structure is even more complicated than the double wishbone and there are many parts, further increasing cost and weight. |

Torsion beam

- ① Shock absorber

- ② Spring

- ③ Knuckle

- ④ Trailing arm

- ⑤ Crossbeam

In this suspension, trailing arms are installed between the body and the wheels, and a crossbeam connects the right and left trailing arms. The crossbeam is called a “torsion beam” because it twists when the vehicle leans during cornering, due to the left and right arms being connected.

【Advantages】A lot of space is available under the floor, since there are no parts cutting across laterally other than the crossbeam. It is possible to tune the handling stability through the combination of crossbeam stiffness and the rubber bushings of the trailing arms. |

【Disadvantages】A pendulum-like gyration tends to occur throughout the suspension, since the attachments of the trailing arms to the body take all the lateral force from the tires. If the gyration is large, it will negatively impact the handling stability. |

Rigid axle suspension

|

【Advantages】

|

【Disadvantages】

|

Standard types

5-link suspension

- ① Shock absorber

- ② Spring

- ③ Axle

- ④ Upper link

- ⑤ Lower link

- ⑥ Lateral link

A suspension design consisting of one long lower link and one shorter upper link attached between the axle and the body (four in all for the left and right wheels) that determine the wheel’s position in the longitudinal direction, and one lateral link that determines its position in the lateral direction, for five links in all.

【Advantages】A simple and inexpensive structure. Handling stability can be ensured to some extent by choosing the location of the five links. |

【Disadvantages】Ride comfort may be poor due to the greater unsprung weight resulting from the axle. |